Safety: Most TFT products are solvent-free and, further, the majority ship NonHazmat. In use, these products generate negligible volatile materials. Unless a potential for a spray generated aerosol exists respiratory protection from standard carbon face masks is adequate. As with all epoxy-based products, it is necessary to avoid excessive or repeated skin contact however TFT materials are less irritating than most competitive materials.

Surface Tolerance: All TFT products share the surface tolerant heritage of its first formulations. These materials were made for underwater applications where excellent adhesion to wet surfaces is required. The built-in surface tolerance allows applications to moist or wet surfaces as well as too compromised or contaminated surfaces such as poorly cleaned vinyl asbestos tile, (VAT), or tight rust.

Ease of Use: TFT formulations are made with the needs of applicators in mind. These are almost always supplied with simple, straightforward mixing ratios of either 1/1 or 2/1 by volume. Competitive products are often sold with mixing ratios such as 3.2/1.0 which makes it very difficult to use partial kits properly. TFT also markets in simple kit sizes such as 2 gallons – easily understood compared to some competitors who sell in cubic inch quantities.

Absence of Odors: In some applications, it is vital to have odor-free coatings. A prime example is flooring for use in facilities such as hospitals. TFT products are almost all odor-free and have had widespread use in areas such as USPS sorting facilities where odors are not permitted.

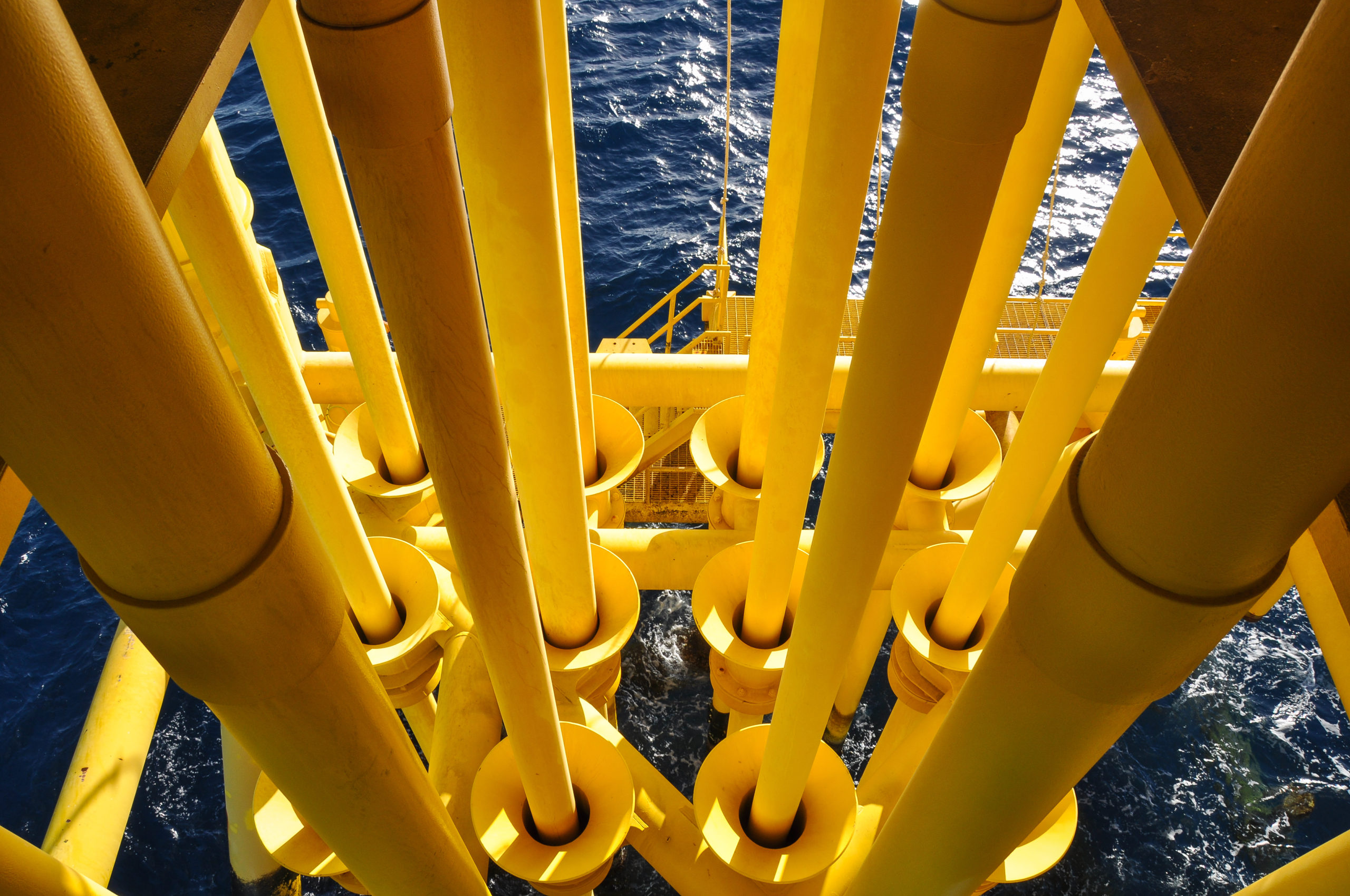

High Performance: TFT products have received approvals for use in extreme conditions such as in nuclear power generating plants. The same technology is applied to a wide range of other coatings for tank linings, secondary containment, or protection of onshore or offshore assets.