The post Product Spotlight: BIO-DUR 560SW appeared first on Thin Film Technology, Inc..

]]>BIO-DUR 560SW is a repair compound that is useful for patching and sealing leaks both above and below water. It creates a glossy, smooth surface on rough steel and concrete while greatly improving abrasion resistance from small particle flows. The formulation is free of solvents that make it easy to apply in confined areas and in order to ensure maximum performance and safety. We use low toxicity ingredients to create a high build brushable/rollable product that is uniquely field-friendly.

This product is unique in that it can be applied above or below the water. To prep the surface before application, it must be high pressure water or abrasive blasted in order to remove any corrosion or organic contamination. Plan to apply BIO-DUR 560SW immediately after underwater surface preparation to prevent the near instantaneous build up of organic matter on the work surface. Above water we always recommend the best surface preparation method achievable, a white metal blast, but you will find that the BIO-DUR 560SW product is extremely surface tolerant of nearly any conditions.

Once mixed, apply the product by hand with a stiff brush or roller. Application by heated plural spray is another easy way to apply to large areas including sheet piling or storage tanks. BIO-DUR 560SW is able to be immersed in water immediately after application provided no extreme flow or impact hits the coating. It is designed and intended for water service at temperatures up to 120 degrees Fahrenheit. For higher temperatures please contact TFT for our other product recommendations.

BIO-DUR 560SW offers the best solution to protecting equipment from damage caused by abrasion, corrosion, and mild corrosive chemicals.

The post Product Spotlight: BIO-DUR 560SW appeared first on Thin Film Technology, Inc..

]]>The post Product Spotlight: BIO-CHIME 390 appeared first on Thin Film Technology, Inc..

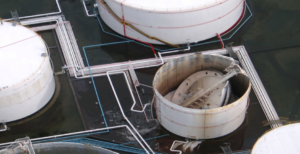

]]>The makeup of this coating makes it a great choice for tank chime areas, since it creates a permanently flexible corrosion resistant seal on the exterior chime surfaces of field storage tanks and similar structures. It can also be used in situations where other joint compounds would soften or fail by solvent or chemical attack.

Most surfaces should be prepped with abrasive blasting before application in order for the coating to adhere well. The next step is the application of BIO-SEAL 197 penetrating sealer over porous concrete in order to minimize or prevent out-gassing. Allow the primer to cure until at least “gummy” before applying BIO-CHIME 390.

For best results, BIO-CHIME 390 should be applied by heated, plural component airless spray. Roller application is not practical, but small aras can be applied by brush or spreader. Typical application thickness is ½”, but be sure it does not exceed 2” because internal overheating from exothermic curing reactions may occur. The coating will be touch dry in 4 hours and fully cured after 24 hours at 77°F or 25°C.

BIO-CHIME 390 is the best permanently flexible thick film coating as it provides corrosion and chemical resistance solutions.

The post Product Spotlight: BIO-CHIME 390 appeared first on Thin Film Technology, Inc..

]]>The post Advantages of Working With a Hands-On Company appeared first on Thin Film Technology, Inc..

]]>Thin Film’s design process only takes about 2-3 days once we receive a request. We suggest an existing formula, or we can take your knowledge to create a unique formula that could work. We create the basis to work from, and then make revisions based on our notes before creating and testing the product in our lab. Once the process is complete, we ship out the finalized product to you.

Larger companies tend to have too many products and projects to even receive a custom request, let alone take the request and finish it out within a week. We’re extremely adaptive and responsive to serve emergency situations, and our team’s creative thinking is crucial to troubleshooting any potential issues. Our process is faster and more efficient because of the size of our team and our company. And because our products are non-hazmat, they can be shipped nationally or internationally as well as being available to be picked up in person by our local customers.

We firmly believe that Thin Film is the best option for your industrial coating needs. Our service and our products are unparalleled, and we look forward to serving you!

The post Advantages of Working With a Hands-On Company appeared first on Thin Film Technology, Inc..

]]>The post Infrastructure and Asset Life Extension appeared first on Thin Film Technology, Inc..

]]>The physical structures of an entity make up the “infrastructure and assets.” These can include drilling rigs, chemical plants, or any other facility.

How can they be protected?

Many structures operate in aggressive environments. These environments allow for attacks to occur on important pieces of the structure. If left unprotected, these damaged assets become unacceptable for safety and can also suffer from economic consequences.

In efforts to protect these structures, we have created polymer solutions that can turn damage and potential disaster into a durable and well-engineered repair. When remedial attention is carefully planned and executed, polymeric resin repair is a very workable practical solution, compared to an uneconomical “hot-work” steel repair.

Examples of Economic Life Extension Projects

- 26,000 sq.ft. of the underwater surface of a neutral buoyancy pool required recoating. The pool was in constant use and recoating in service was required. TFT supplied special underwater applied coatings to enable the pool to remain in service, without draining, during the recoating project. (See Case History #065)

- A large platform in the North Sea had badly corroded, damaged, and sagging decks but removing and replacing the affected areas would have been uneconomical. An engineering solution was proposed that involved laying new lightweight steel over the existing deck using an epoxy resin as the adhesive. TFT formulated a custom low modulus, highly adherent epoxy resin that was poured into the void spaces between the old and new decks eliminating potential corrosion cells. The project was completed in a short time with perfect results, minimal downtime, and costing a fraction of the price for a total overhaul. (See Case History #067)

- A nuclear submarine had a leak in a heat exchanger located several decks deep. The location of the heat exchanger made it a time consuming and expensive proposition to remove it for a topside repair. TFT formulated a special, water-tolerant injectable repair compound that was able to effectively seal off the defective exchange tube in a simple overnight maintenance operation. (See Case History # 063)

- Anticorrosion coating of structural steel where proper surface preparation is not always possible is made possible with TowerGard 568. This product was specially developed for use on structures such as microwave towers which can be very high and are often wet. TowerGard 568 is a one-coat, high build, and easy to use anticorrosive coating designed for exactly these applications. (See Case History # 061)

Conclusion

It is possible to use modern polymeric repair materials to repair and increase the remaining service life of existing assets that would otherwise be impossible or substantially more costly using conventional techniques.

The post Infrastructure and Asset Life Extension appeared first on Thin Film Technology, Inc..

]]>The post Product Spotlight: SINK-NOT 350 appeared first on Thin Film Technology, Inc..

]]>The SINK-NOT 350 was created to perform as a final solution to sinking roofs in pontoons due to corrosion, rainfall, etc. The product is a void-filling, closed-cell polyurethane foam. While it stops roofs from sinking and leaking, it also stops vapor emissions, reduces fire threat, increases roof stability, and can be completed quickly.

Long-Lasting Durability

SINK-NOT 350 has been used in floatation services, lasting as long as 18 years with no failures in various media including the following:

- Crude Oil

- Gasoline

- Water

- Naphtha

- Xylene

- Jet Fuel

- Diesel

- Toluene

The foam can actually incorporate and “tie-up” small amounts of product leftover or residue. It will expand into the smallest holes and voids. Because of its product resistant properties, SINK-NOT 350 will seal the holes and voids, thus providing another layer of protection from future leaks and corrosion.

Safety & Installation

SINK-NOT 350 is hydrocarbon resistant, it will not sustain a flame. The closed-cell, chemical resistant foam prevents vapors from escaping into the atmosphere. Because it is a closed-cell foam, it can not be absorbed or dissolved by the media it contacts!

To install, the foam is injected and allowed to rise in several continuous layers until the pontoon is completely filled. When full, any excess is trimmed from the manway. It is pumped directly from the drum, using an airless plural pump application.

SINK-NOT 350

SINK-NOT 350 offers an excellent solution to leaking pontoons that can result in devastating and costly roof collapses while at the same time providing value-added corrosion protection and the ability to “tie up” existing residual media.

The post Product Spotlight: SINK-NOT 350 appeared first on Thin Film Technology, Inc..

]]>The post When To Use TFT Products appeared first on Thin Film Technology, Inc..

]]>Surface Tolerance: All TFT products share the surface tolerant heritage of its first formulations. These materials were made for underwater applications where excellent adhesion to wet surfaces is required. The built-in surface tolerance allows applications to moist or wet surfaces as well as too compromised or contaminated surfaces such as poorly cleaned vinyl asbestos tile, (VAT), or tight rust.

Ease of Use: TFT formulations are made with the needs of applicators in mind. These are almost always supplied with simple, straightforward mixing ratios of either 1/1 or 2/1 by volume. Competitive products are often sold with mixing ratios such as 3.2/1.0 which makes it very difficult to use partial kits properly. TFT also markets in simple kit sizes such as 2 gallons – easily understood compared to some competitors who sell in cubic inch quantities.

Absence of Odors: In some applications, it is vital to have odor-free coatings. A prime example is flooring for use in facilities such as hospitals. TFT products are almost all odor-free and have had widespread use in areas such as USPS sorting facilities where odors are not permitted.

High Performance: TFT products have received approvals for use in extreme conditions such as in nuclear power generating plants. The same technology is applied to a wide range of other coatings for tank linings, secondary containment, or protection of onshore or offshore assets.

The post When To Use TFT Products appeared first on Thin Film Technology, Inc..

]]>The post Underwater Coating: NASA Style! appeared first on Thin Film Technology, Inc..

]]>The astronauts use this pool to train in a weightless environment, learning how to operate in what feels like outer space. Being underwater, the astronauts are able to practice simulating extravehicular activities and learn how to operate comfortably in their suit. With our underwater applied coating, BIO-DUR 560, and a great team of divers, we were able to work on recoating the pool without interrupting NASA’s training at the NTB. This allowed astronauts to continue on schedule as we rotated divers and worked in sections to apply a barrier coating over the existing concrete that was suffering from rust and corrosion.

Initially, we completed the North wall of the pool, doing observations, basic tests, and a later examination proving outstanding condition, we were set to complete the remaining walls! The fresh coating has dramatically improved both the appearance and illumination underwater. Going from stained and splotchy to snow white!

This project was both exciting and rewarding for Thin Film Technology and partners involved. We look forward to sharing more project spotlights with you!

The post Underwater Coating: NASA Style! appeared first on Thin Film Technology, Inc..

]]>The post The Nuclear Option: Coating a Power Plant appeared first on Thin Film Technology, Inc..

]]>November, 2014

coatingspromag.com

Nuclear power plants operate under some of the strictest quality control and maintenance schedules. All major maintenance is carried out during brief outages. During one such outage, the emergency water storage tank, the torus, located beneath the nuclear reactor needed to be drained and coated to prevent corrosion in the metal structure. The torus was only accessible through two 54-inch man holes. Due to the confined area of work, heated plural spray with a 400 foot hose was used to spray 100% solids, nonhazardous Bio-Dur 560 over 32,000 sq.ft. of steel.

The post The Nuclear Option: Coating a Power Plant appeared first on Thin Film Technology, Inc..

]]>The post A New Face on an Old Problem appeared first on Thin Film Technology, Inc..

]]>March, 2006

paintsquare.com

The Snowdonian Stwlan buttress dam near Blaenau Ffestiniog is a pumped storage hydroelectric power station. Constructed in 1963, the concrete dam utilized a unique double wedge joint between each buttress. These joints were never sealed properly creating seasonal freeze/thaw damage that ultimately lead to worsening spall damage of the structure itself. In 2000, manufacturers were invited to test their products in an extended two year trial. After multiple evaluations, Thinfilm Technology was selected to apply 100% solids coating that would eventually cover 2,050 sq.m. of concrete surface.

The post A New Face on an Old Problem appeared first on Thin Film Technology, Inc..

]]>